Most air compressors (for example, California Air Tools compressors) that cost a lot of money are quieter. However, not everyone can afford those. Therefore, we were seeking something practical that could help you to get a quieter air compressor.

In this article, we’ll explain why your air compressor generates noise and show you how to reduce the air compressor noise expertly.

Contents

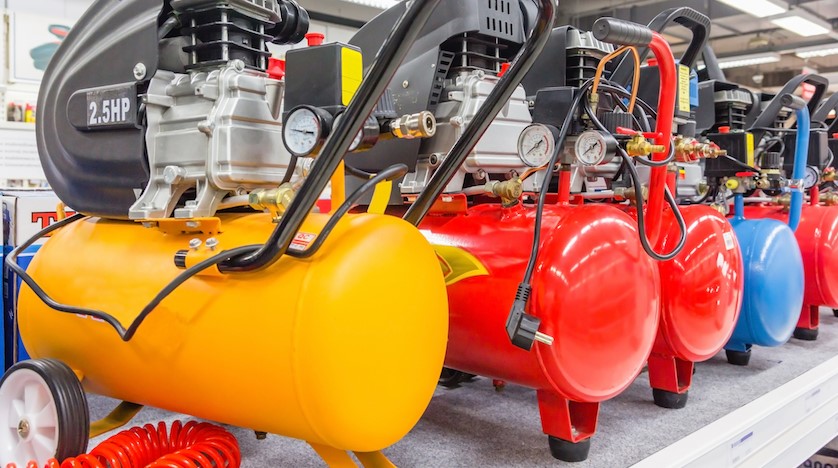

Types of air compressors

It would be best to explore the different types of air compressors available and take a closer look at the air compressor inside before we analyze how to lower the air compressor noise level:

- Centrifugal compressors, sometimes known as radial compressors, are frequently employed in turbomachinery applications. The compressor’s impeller (rotor) is used to move fluid. As a result, the device’s internal pressure is increased by velocity.

- Gas, axial, or turbo compressors are all terms used to describe a device that rotates an airfoil to produce gas pressure.

- Spiral or scroll compressors move circularly, as their names suggest. Since they can carry both air and refrigerant, they are frequently used in air conditioning systems.

- Rotor movement within the chamber is made possible by the vanes included in rotary vane compressors.

- Rotary screw compressors. This type of air or gas compressor, which can produce extremely high air pressure volumes, is a positive displacement device (more on this later). It’s better to use a rotary screw air compressor for a jackhammer or impact wrench.

- Compound compressors are made up of several cylinders installed in stages. The first cylinder receives the air, which is compressed there before cooling. Then it is transferred to another cylinder and crushed even further.

- A single-stage reciprocating compressor compresses air only once.

- Similar to the previous example, a two-stage reciprocating compressor is employed when air is compressed, passed through an intercooler, and then compressed even further.

Your air compressor noise levels may just be 40-45 dB if you’re lucky. More than 90 dB can be produced by larger, heavier devices.

For comparison, the noise level of a vacuum cleaner ranges from 60 to 85 decibels.

The majority of lawnmowers operate at 90 decibels. At that volume, there is a risk of hearing loss.

Even yet, regular exposure to loud objects between 80 and 90 dB may eventually cause hearing damage. If you use your air compressor frequently enough, you can begin to lose your hearing before you should.

Why is my air compressor so noisy?

So, the moment has come to identify the root cause before we learn methods of quieting air compressors. Several things influence how loud an air compressor is.

If those elements are the problems in your situation, you can effectively deal with them. The factors that impact sound are listed below.

Vibration

The vibration of the entire machine is the primary factor for the higher noise level in air compressors. Even though it won’t be the main aspect, the issue of producing noise is still quite important.

An air compressor’s vibration is mostly influenced by the type and installation. There is a significant risk that the air compressor will start vibrating a lot if you assemble it incorrectly.

Again, even if you assembled and installed the air compressor correctly, some sections of the machine can still cause it to generate a lot of noise.

Vibration intensity rises if any machine component is improperly attached to the compressor.

This is associated with the location as well. The vibration is not absorbed by the hard surface, therefore it gets worse. The overall noise level rises thus.

Materials of air compressor components

The raw materials utilized in the air compressor’s manufacture are crucial. For instance, if you purchase a cheap item made of thin metal materials and use it at home, you can be sure that it will be noisy. The reason for this is that thin metal vibrates more and produces more sound.

On the contrary, a few well-known brands manufacture air compressors using premium components. Less vibration is advantageous in this case. As a result, the noise level is below acceptable limits.

Installation location

The location has a significant impact on the air compressor noise level. For instance, the machine will likely produce more noise while running if you’ve stored it on a hard surface and lacks adequate ventilation.

Additionally, louder noises may result from objects that shake a lot while in use. Furthermore, the air compressor won’t operate effectively if the surface is uneven. Make sure the compressor is positioned on a level surface.

Air intake and air exhaust

The air intake part of the air compressor is another factor that disrupts noise reduction. Its operation can be compared to that of a vacuum cleaner.

During operation, an air compressor also produces this type of air. This may produce a loud noise.

One of the loudest parts of a noisy air compressor is the exhaust. Without the right exhaust system, an air compressor will produce intolerable noise.

How to make an air compressor quieter?

You can take several actions as an air compressor user to address the noise issue. Here, we’ll go over the top strategies for lowering noise levels to bearable levels.

Reposition the air intake

An essential component of the air compressor is the air intake. You can relocate the intake if you’d want to be less bothered by its noise.

Some owners of air compressors have tried using garages, basements, or garden sheds. The issue with the basement or the garage is that your house is still connected to these spaces.

You would undoubtedly hear the air compressor in your garage or basement, even if it would be quieter than if it were next to you.

Because of this, some individuals have chosen to move it outside. The compressor is quieter in a backyard or a side yard because of the space’s openness. Additionally, since it would be farther away from your home, you would hear your air compressor even less.

If at all possible, bury the other end of your hose a few inches underground. This hose end can be fixed precisely where you want it to be using grommets or brackets. The noise of the air compressor will be lower if the hose is securely fastened.

Apply rubber grommets to the air compressor

A common noise-absorbing material used for much different equipment is rubber. For instance, you will notice that kitchen sinks made of stainless steel have a rubber coating underneath them to lower the noise level. You can do the same thing for an air compressor.

The rubber grommet needs to be positioned between the air compressor and the surface it is mounted on.

The rubber will lower the noise level by reducing vibration the next time you use the air compressor.

Accurate measuring is necessary for rubber placement. Ensure that everything remains flat after the rubber has been applied. If everything is done correctly, the noise of your air compressor should be reduced. While it won’t be completely silent, the noise level will be bearable.

Nothing to worry about if you’re wondering where to get this rubber item. Any tool store has it in stock. They are also available through online retailers.

Lubricant the bearings

Any machine with movable elements has bearings. The same is true of an air compressor. The bearings will therefore move in various directions as the compressor is working.

There will then be some metal-on-metal friction at that point. This will result in loud noise. So, the metal will get damaged and you won’t be able to use the compressor for a very long time.

Therefore, the user’s option for reducing friction and noise is to lubricate the bearings. The process of lubricating metal items is simple.

There are many different items available that ensure uniform metal-to-metal friction. You can choose the best bearing grease available. Apply the lubricant correctly, let it rest for a bit, and then turn on the compressor. This is a straightforward yet efficient method for getting a quiet air compressor.

Sound-deadening materials

We have previously advised inserting a rubber between the compressor and the hard surface. You can apply the same technique to the compressor’s surrounding walls. Why does this work? You will hear more noise if you position the compressor close to a wall since the sound will reverberate. It will also occur if you put the compressor in a tight space.

So, you can reduce noise by mounting something soundproof on the wall. You do not need to utilize rubber grommets in this situation. Use the wall padding that is soundproof in its place. There are sound blankets available in stores that can function perfectly.

It’s not necessary to cover every wall in the room where the compressor is located with padding. Instead, all that has to be done to prevent echoing is to fasten the padding to the compressor’s adjacent wall.

Build an air compressor soundproof box

Building a soundproof box requires more DIY work. However, it’s a highly effective approach to the quieter air compressor. This is the greatest choice, according to the majority of people on various forums and other websites. Generators are commonly muffled using soundproof enclosures.

Put the air compressor in a soundproof enclosure to significantly reduce noise. The most popular materials for building a soundproof box are plywood or MDF panels. Either is available in retailers in bespoke sizes.

To build this box, you’ll need a circular saw, a drill, and screws. To ensure that the wooden box will be large enough to accommodate the air compressor, first measure the compressor.

If you’re utilizing an air hose or another extension of the compressor outside the box, you’ll also need to drill some points in the box.

To add a layer of sound insulation, you can ultimately cover the box once you’ve built it using screws or nails and wooden panels.

Cover it with the soundproofing material of your choosing from the inside or the outside (or both). Mass Loaded Vinyl does an excellent job of dampening impact sounds. It’s also fairly affordable.

The best materials to make an air compressor quiet are often mass-loaded vinyl and fiberglass. Since soundproofing foam only serves to dampen echoes and airborne sounds, we would advise using it.

Spray the wooden surface or one side of the material with a spray adhesive before attaching it to the box. You can use any spray adhesive. The majority of my tasks call for 3M General Purpose Spray. After that, adhere the material to the box’s outside.

Depending on how you created it, you can now either put the air compressor within the box or put the box above the air compressor. The most crucial factor is that a large portion of the open area through which sound can readily enter the remainder of the room has been covered. This is comparable to creating a tiny room with thick walls just for the air compressor.

However, don’t anticipate total soundproofing. In other words, don’t expect complete noise reduction. Since the box needs to have openings for heated air to escape and for fresh air to enter, sound can also travel through the unfilled spaces. But compared to before, it will be far lower.

This approach will be to time- or effort-consuming for the majority of readers. So here’s a less complicated approach that may also be useful to make an air compressor quiet.

Add the soundproofing cover to the air compressor motor

Don’t worry if you don’t feel like constructing a wooden box and wrapping it in soundproofing material. Instead, you can directly cover the motor of the compressor with the soundproofing material. Even though the results will be less strong, they will still be evident. How specifically do you do this?

You can employ a substance that absorbs impact noise. It is simpler to utilize one of the several anti-vibration mats available for use in soundproofing automobiles for this purpose.

Place the material across the air compressor’s motor in one or two layers. You’ll add another sound-absorbing barrier by doing this. This approach is particularly helpful for a loud compressor with thinner steel structures.

The motor compartment of purportedly “quiet air compressors” (that are those noisy air compressors) has additional soundproofing material. Of course, next to a stronger metal casing. They may be up to 30 dB quieter than their rivals on the market as a result.

This DIY approach uses the same methodology and costs a lot less money.

However, results will necessarily differ from one compressor to another because the thickness of the metal construction also factors into this.

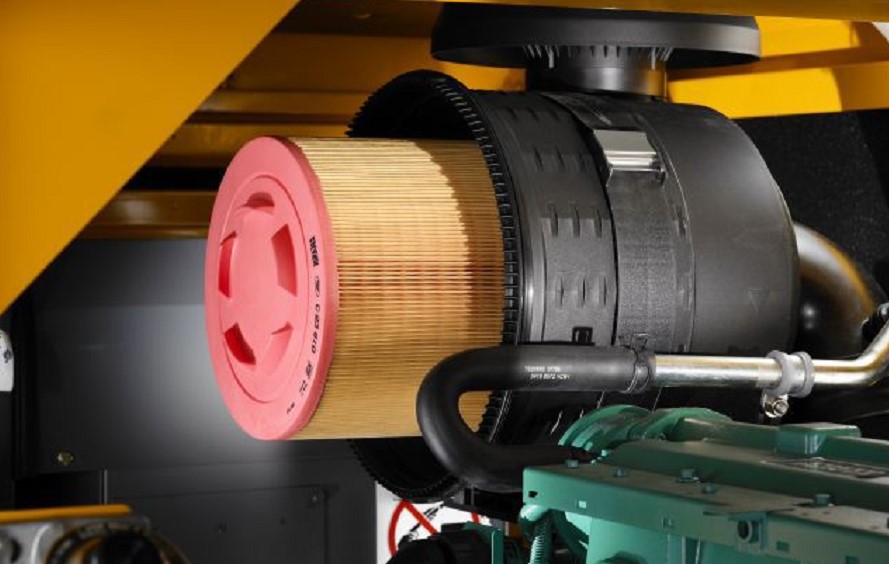

Try to clean the air filters

As you undoubtedly already know, air filters collect dirt particles. Their primary function is to catch the dirt that would otherwise enter through the air intake valve.

Air filters, however, do not clean themselves. After a while of use, they need to be cleaned out. The dirt may start migrating through the system and impede the compressor’s operation if they are not cleared if they are clogged. Additionally, it will prevent ambient air from entering cylinders.

All of this may result in even more noise. Therefore, clearing the air filters is crucial. For routine use, once a year is usually sufficient for maintenance. If you frequently use the air compressor, it is advised to unclog it more frequently (once every 6 to 8 months).

FAQ

How do I quiet down my Harbor Freight air compressor?

To do this, you can use any of these techniques that we’ve offered. You only need to use one or two strategies to complete the task and get an air compressor quiet.

How can I make my oil-free air compressor quieter?

To make the intake of your oil-free air compressor quiet, use a sound muffler. You may attach a device to your oil-free compressor to assist reduce noise levels by about 2 decibels, much like a car has an exhaust muffler.

Conclusion

Keep in mind that you are not the only one who is affected by your compressor’s noise problem as you work to resolve it. Almost all air compressor users occasionally run into this problem. These techniques have been successfully used for a long time by professionals to get a quiet air compressor.

However, while the compressor is working, always use earplugs to protect your hearing. This will stop any noise-related health problems.

Read More: How To Make An Air Compressor Quieter