Air compressors are essential tools for many different industries, from automotive and construction to manufacturing and beyond. They are used to power a variety of pneumatic tools and equipment, from nail guns and impact wrenches to sanders and grinders.

However, one of the most common issues that users encounter with air compressors is when they won’t shut off. They panic. What needs to be done to make the air compressor shut off?

In this blog, we’ll explore the most common reasons, why an air compressor won’t shut off, and what you can do to fix the problem.

Contents

- 1 Reasons, Why Your Air Compressor Won’t Shut Off

- 2 Solutions to Fix Your Air Compressor

- 2.1 Inspect the Check Valve

- 2.2 Check for Air Leaks

- 2.3 Clean the Air Filter

- 2.4 Inspect the safety valve

- 2.5 Address Mechanical Issues

- 2.6 Verify Proper Electrical Wiring

- 2.7 Consider Ambient Temperature

- 2.8 Check for Incorrect Tank Size

- 2.9 Inspect tank Pressure Relief Valve

- 2.10 Follow Maintenance Schedule

- 3 Why does my air compressor not stop running?

- 4 What happens if the compressor runs continuously?

- 5 How do air compressors know when to shut off?

- 6 Why won t my compressor reach cut-off pressure?

Reasons, Why Your Air Compressor Won’t Shut Off

Faulty Pressure Switch

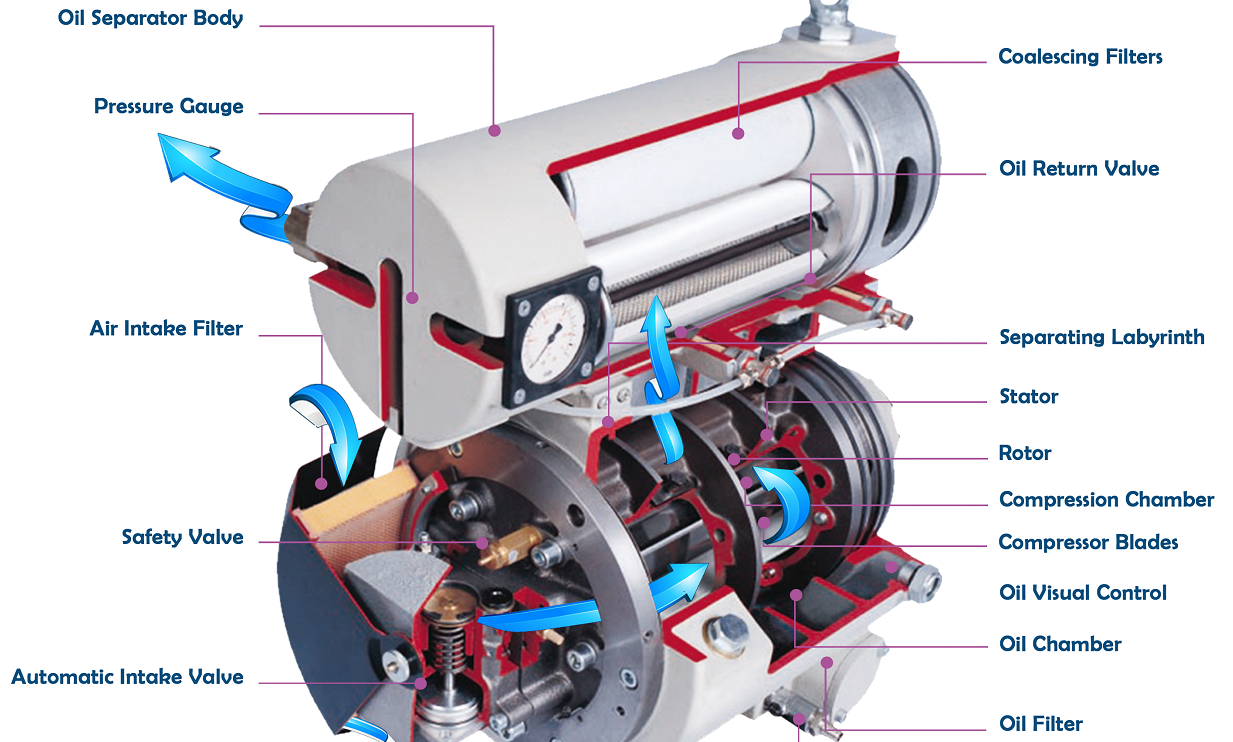

The air compressor pressure switch is a crucial part, responsible for starting or stopping the motor as the air pressure in the tank changes.

The pressure switch deactivates the motor of the air compressor when the pressure in the tank gets over the determined level and fulfills its potential maximum.

If the compressor pressure switch is not working properly, it could lead to bad consequences, such as the air compressor working continuously without stopping despite the tank pressure reaching full up.

Check Valve Failure

The primary function of the tank check valve is to ensure that air can move in only one direction, thereby preventing the compressed air from reversing back into the compressor pump.

If the check valve malfunctions or gets jammed open, it can permit air to stream back into the pump, resulting in the compressor running continuously.

Air Leak

The compressor will continue to run to maintain more pressure if there is a leak in the air system. Inspect the tank connections, fittings, and hoses for leakage. Another factor that could contribute to a leak is a broken pressure switch or tank pressure regulator.

Dirty Air Filter

The compressor may have to work harder and operate constantly if an air filter is clogged, which restricts the amount of air entering it. To avoid this, check and clean the air intake filter frequently.

mechanical breakdown

Sometimes the compressor pump can run constantly due to a mechanical issue. This might be the result of, for instance, a damaged crankshaft or a worn-out piston ring.

Solutions to Fix Your Air Compressor

Check the Pressure Switch

The pressure switch is crucial in controlling how often an air compressor turns on and off. Even though the air compressor tank pressure is too high, if the pressure switch isn’t working properly, the air compressor may operate continuously. It might be essential to purchase a new pressure switch to solve this problem.

If you’re experiencing this problem with your air compressor, don’t worry.

To check the pressure switch, first, make sure the power is turned off and disconnected from the air compressor. Then, locate the pressure switch and remove the cover to expose the electrical contacts. Check for any signs of corrosion, damage, or wear on the contacts, diaphragm, or switch housing.

If you notice any of these issues, a replacement pressure switch is needed.

Replace the damaged pressure switch with a new pressure switch. Also, check the air pressure settings on the pressure switch to make sure it matches the compressor’s rated pressure.

Inspect the Check Valve

Before checking the tank check valve, turn off the compressor’s electricity and let all the pressure in the tank escape. After that, disconnect the valve’s connection from the tank and the pump before checking them for signs of wear or harm.

If the check valve is damaged or stuck open, swap it out for a new one. Additionally, make sure the check valve is installed properly. If it is, the air compressor might run continuously.

Check for Air Leaks

Air leaks can be challenging to locate, but they are a common cause of air compressors that won’t shut off.

A leak could also be caused by a faulty regulator or valve. To check for air leaks, first, turn off the power to the compressor and activate the tank pressure release valve so all the air pressure in the tank goes out.

Then, use a soapy water solution to identify air leaks. Apply the solution to the connections and watch for bubbles. If you identify any air leaks, tighten or replace the faulty component to fix the issue.

Clean the Air Filter

The air filter is responsible for removing dust and debris from the air that the compressor draws in. A dirty air filter can restrict the flow of air into the compressor, causing it to overwork and run continuously.

Check the air filter regularly and clean or replace it as needed. Remove the air filter from the compressor to clean it, then blow any grime or debris out of it with compressed air or wash it down with soapy water. Before replacing the air filter, make sure it is dry.

Inspect the safety valve

It is designed to release air from the compressor if the pressure exceeds a certain level. If it is faulty or blocked, it may prevent the compressor from reaching the cut-out pressure level. To inspect it, turn off the compressor and disconnect the air hose. Then, remove the safety valve and clean it or replace it if necessary.

Address Mechanical Issues

Are you still having problems with your air compressor not shutting?

If you have checked all the above and the compressor still won’t shut off, there may be mechanical issues with the air compressor pumps. Mechanical issues could be caused by a worn-out piston ring or a damaged crankshaft, for example. In this case, it’s best to consult a professional technician to diagnose and fix the issue.

They may need to disassemble the pump and inspect the internal components to determine the root cause of the problem. Depending on the extent of the damage, they may recommend repairing or replacing the pump.

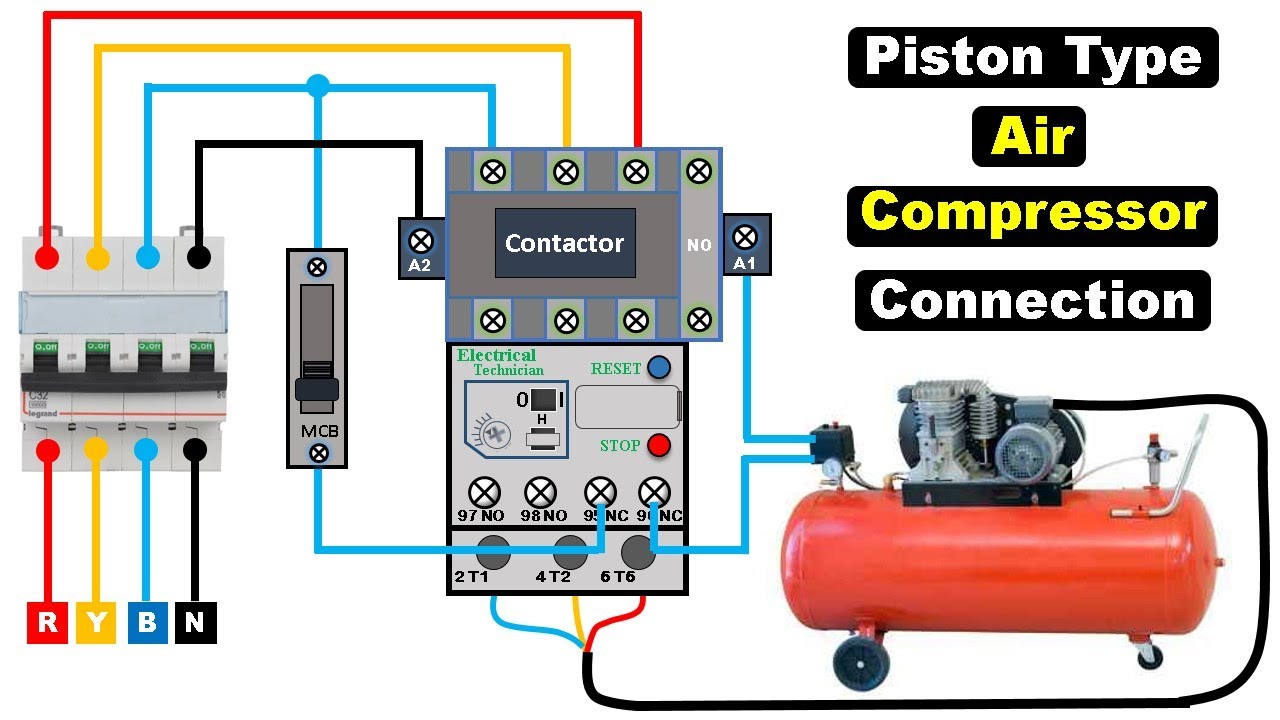

Verify Proper Electrical Wiring

Electrical wiring issues can also cause an air compressor to continuously run. Verify that the compressor is wired correctly, with the proper voltage, and that all wiring connections are secure.

Check for any loose, damaged, or frayed wiring that could be causing a short circuit. If you notice any wiring issues, disconnect the power supply and consult an electrician to fix the problem.

Consider Ambient Temperature

The ambient temperature can also affect the operation of an air compressor. If the compressor is located in the area that is too hot, it may cause the compressor to run continuously.

Check the manufacturer’s specifications for the recommended operating temperature range and ensure that the compressor is located in the area that falls within that range. If the compressor is located in a hot area, consider installing a fan or ventilation system to help cool the compressor.

Check for Incorrect Tank Size

If the compressor is continuously running, it could be due to an undersized tank. An undersized tank may not have enough capacity to hold the air, causing the compressor to continuously run to keep up with the demand.

Check the manufacturer’s specifications for the recommended tank size for your compressor and make sure the tank size is sufficient for your needs. If the tank is undersized, consider upgrading to a larger tank or purchasing a new compressor with a larger tank.

Inspect tank Pressure Relief Valve

An air compressor may operate continuously if the pressure relief valve is broken. When the air pressure in the tank hits a specific point, the pressure relief valve is intended to open and let all the air out.

The air compressor might have to run constantly if the pressure relief valve is broken or stuck open. Make sure the valve is working properly by checking it, and replace it if required.

Follow Maintenance Schedule

Regular maintenance is crucial to keep your air compressor functioning correctly. Follow the manufacturer’s recommended maintenance schedule, which typically includes tasks such as oil changes, filter replacements, and inspections.

Neglecting routine maintenance can cause issues that lead to the compressor running continuously. By following a regular maintenance schedule, you can catch issues early and prevent more significant problems from developing.

Conclusion

In conclusion, an air compressor that won’t shut off can be frustrating and can cause damage to the compressor if left unchecked.

By following the steps outlined above, you can diagnose and fix the issue, ensuring that your compressor is functioning correctly and efficiently.

If you are unable to determine the cause of the problem or are uncomfortable performing any of the above steps, consult a professional technician for assistance.

FAQ

Why does my air compressor not stop running?

An air compressor that does not stop running can be a frustrating problem for its users. There are several potential reasons why a compressor may not shut off, and it is important to identify the root cause before attempting to fix the issue.

A compressor can keep running without stopping because the pressure switch fails. The pressure switch has the duty of controlling the on and off function of the compressor, which is determined by the pressure in the tank.

If the switch is faulty or malfunctioning, it may not shut off the compressor when the tank pressure reaches the maximum level. In this case, it is necessary to check the pressure switch for any damage, corrosion, or loose connections. If any issues are found, the switch should be replaced. After that, check again. Everything is fine if the pressure switch trips.

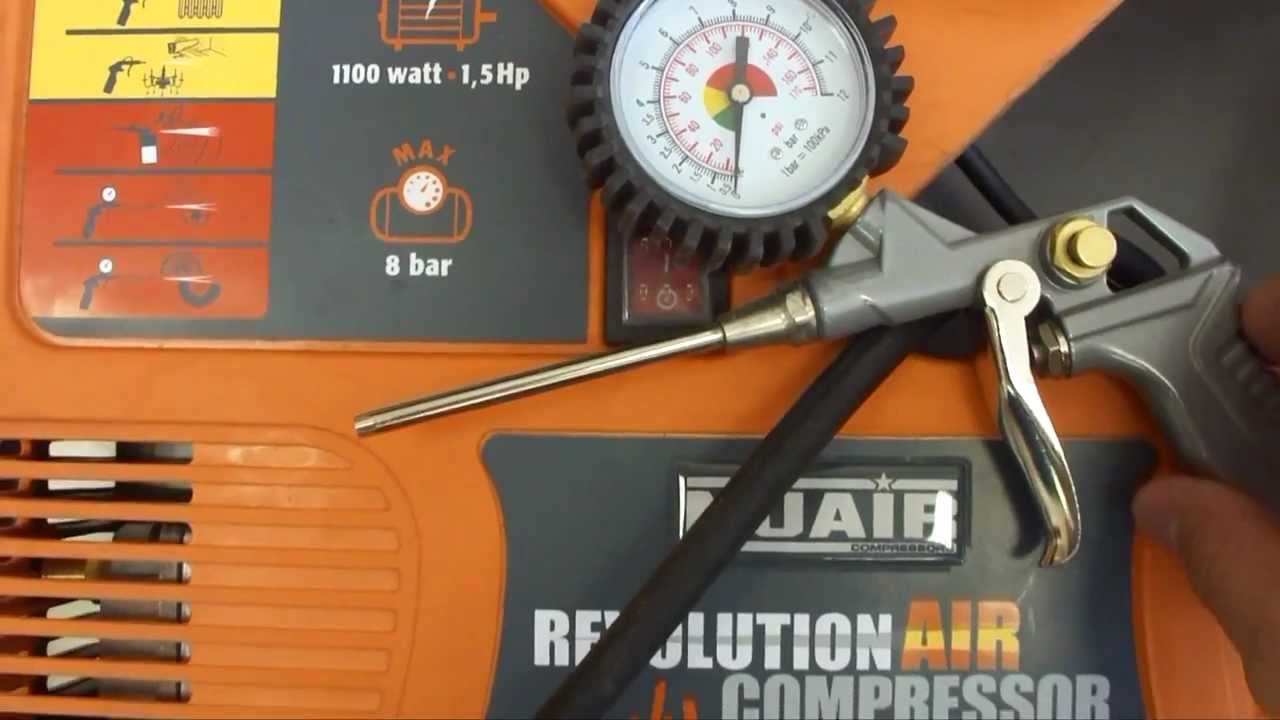

Another potential cause of the issue is a faulty pressure gauge. The gauge on the compressor indicates the air pressure in the tank. If the gauge is faulty or damaged, it may not accurately display the pressure level, leading to the compressor running continuously.

To fix this issue, it is necessary to turn off the compressor, disconnect the power supply, and inspect the pressure gauge for any damage or debris that could be blocking the needle. If the gauge is damaged, it should be replaced.

A damaged or leaking air line can also cause a compressor to continuously run. If there are any cracks, holes, or leaks in the airline, air may be escaping, causing the compressor to run continuously.

To check the airline, it is necessary to turn off the compressor, disconnect the power supply, locate the airline, and inspect it for any damage or leaks. If any damage is found, the airline should be replaced.

The oil level in the compressor is crucial to its operation. Low oil levels can cause the compressor to run continuously and may lead to damage.

To verify the oil level, it is necessary to turn off the compressor, disconnect the power supply, locate the oil fill tube, and remove it. The oil level should be checked using the dipstick provided by the manufacturer. If the oil level is low, it should be added as necessary.

The dirty or clogged air filter can restrict airflow, causing the compressor to run continuously. To fix this issue, it is necessary to check the air filter and clean or replace them if necessary. Regular maintenance and inspection of the compressor can help prevent these issues from occurring.

Overuse or overheating can also cause the compressor to not stop running. If the compressor has been in use for an extended period, it may need to cool down before it can be used again.

Faulty valves can also cause the compressor to not stop running. The intake valve or outlet valve may be stuck open, allowing air to continuously flow through the system.

What happens if the compressor runs continuously?

With the air compressor not shutting off, it can lead to a range of negative consequences that can affect both the compressor and its surroundings. In this section, we will explore these consequences in more detail.

One of the most significant risks of a compressor that runs continuously is damage to the compressor itself. Overuse and overheating can cause the components of the compressor to wear out, leading to mechanical failures and a reduced lifespan for the machine. This can result in expensive repair bills or even the need to replace the compressor altogether.

In addition to damaging the compressor, continuous operation can also lead to increased energy costs. A compressor that runs continuously consumes more energy than one that runs only when necessary.

This can lead to higher energy bills, which can be a significant expense for businesses that rely on compressed air. To reduce energy consumption, it is important to identify the root cause of the continuous operation and take appropriate action to fix the issue.

Another consequence of a compressor that runs continuously is reduced efficiency. As the compressor continues to run, the components may become less effective at compressing air, leading to longer cycle times and increased energy consumption. This reduced efficiency can result in increased wear and tear on the compressor and a shorter lifespan for the machine.

Overheating is another potential consequence of continuous compressor operation. As the compressor continues to run, it generates heat, which can cause the components to overheat and malfunction. Overheating can cause the compressor to fail or even catch fire, which can be hazardous to workers and damage the equipment.

Another risk of a compressor that runs continuously is pressure build-up. If your air compressor is building pressure and does not seem to stop, it could be a sign of a few different issues.

Not stopping building pressure may lead to the tank rupture if the tank pressure reaches a dangerous level. This can result in potential safety risks and significant damage to the compressor and surrounding equipment.

To prevent these negative consequences, it is important to identify the root cause of the continuous operation and take appropriate action to fix the issue.

Regular maintenance and inspection of the compressor can help prevent these issues from occurring in the first place.

Additionally, it is essential to follow proper safety protocols when working with air compressors, such as wearing appropriate personal protective equipment and ensuring that the compressor is properly grounded.

How do air compressors know when to shut off?

If your air compressor is not reaching the cut-off pressure, it may be due to a variety of reasons. In this section, we will explore some of the common causes of this issue.

Leaks in the Air System

One of the most common reasons for a compressor not reaching cut-out pressure is air leaks in the system.

These leaks can occur in various parts of the system, such as hoses, fittings, valves, and even the compressor tank itself. When there are leaks in the system, the compressor has to work harder to maintain the desired pressure, resulting in reduced efficiency and longer cycle times.

Malfunctioning Pressure Switch

The pressure switch is an essential part that is responsible for the work of the compressor motor. It turns on or turns off the motor where needed.

If the pressure switch is malfunctioning, it may not allow the compressor to reach the cut-out pressure, resulting in continuous operation. This can be caused by a faulty switch or improper adjustment of the switch settings.

Dirty Air Filter

A dirty air filter can be another cause for a compressor failing to reach the cut-out pressure. This occurs when the filter accumulates dirt and debris, causing blockages. It restricts the flow of air to the compressor, reducing its efficiency and preventing it from reaching the desired pressure level.

Worn or Damaged Valves

The compressor valves are responsible for controlling the flow of air into and out of the compressor.

Over time, these valves can become worn or damaged, leading to reduced efficiency and lower tank pressure levels. This can also cause the compressor to run continuously and fail to reach the cut-out pressure.

Low Power Supply

The compressor motor requires a certain amount of power to operate effectively. If the power supply is low or fluctuating, the motor may not be able to reach its full potential, resulting in reduced efficiency and lower pressure levels.

Why won t my compressor reach cut-off pressure?

When an air compressor fails to reach the cut-out pressure, it can be frustrating and costly in terms of wasted energy and reduced productivity. In this section, we will explore the common causes of this issue in more detail.

Air Leaks in the System

However, another cause of the air compressor not shutting off is air leaks, including failing to reach the cut-out pressure.

When there are leaks in the system, the compressor has to work harder to maintain the desired tank pressure, resulting in reduced efficiency and longer cycle times. Common areas where air leaks can occur include hoses, fittings, valves, and the compressor tank pressure itself.

To identify and fix air leaks, you can perform a leak test using a soapy water solution. Apply the solution to all connection points and watch for bubbles forming, indicating air leaks. Once identified, leaks can be fixed by replacing or repairing the affected component.

Malfunctioning Pressure Switch

Depending on the pressure inside the air tank, the pressure switch is in charge of turning the compressor motor on and off. If the pressure switch is broken, the compressor might not be able to achieve the cut-out pressure, which would cause it to run continuously. This can be caused by a faulty switch or improper adjustment of the switch settings.

To diagnose and fix pressure switch issues, you can perform a continuity test on the switch using a multimeter. If the switch fails the test, it may need to be replaced. Adjusting the switch settings may also help to resolve the issue.

Dirty Air Filter

A dirty air filter can cause the compressor to fail to reach the cut-out pressure by restricting the flow of air to the compressor, reducing its efficiency. It is essential to regularly clean or replace air filters to prevent this issue from occurring.

To clean an air filter, remove it from the compressor and gently tap it to remove any loose dirt and debris. You can then wash the filter in a solution of warm water and detergent and let it air dry before reinstalling it. If the filter is damaged or heavily soiled, it may need to be replaced.

Worn or Damaged Valves

The compressor valves are responsible for controlling the flow of air into and out of the compressor. Over time, these valves can become worn or damaged, leading to reduced efficiency and lower pressure levels. This can also cause the compressor to run continuously and fail to reach the cut-off pressure.

To diagnose and fix valve issues, you can perform a visual inspection of the valves for signs of wear or damage. If the valves are worn or damaged, they may need to be replaced.

Low Power Supply

The compressor motor requires a certain amount of power to operate effectively. If the power supply is low, the motor may not be able to reach its full potential, resulting in reduced efficiency and lower pressure levels.

It is important to ensure that the compressor is connected to a stable and adequate power supply to prevent this issue.

Cut-out pressure setting

If the cut-out pressure level of your air compressor is not working properly, you should take immediate steps to diagnose and fix the issue.

To fix it you need to check the cut-out pressure setting of an air compressor.

You need to locate the pressure switch and adjust the cut-out pressure setting.

Turn off the compressor and remove the cover from the pressure switch. Use a gauge to measure the current cut-out pressure setting configuration. To adjust the cut-out pressure setting, use a flathead screwdriver to turn the pressure adjustment screw on the pressure switches clockwise to increase the pressure or counterclockwise to decrease it.

Check the pressure level again with the gauge to ensure it is at the desired level. Replace the cover on the pressure switch and turn the compressor on to test it.

Thank you

As we come to the end of this blog, I would like to take a moment to express my heartfelt gratitude to all of you, our readers, for taking the time to engage with this content. It is only through your support and engagement that we can continue creating informative and valuable resources like this one.

I want to thank every one of you for your time and attention in reading this blog.

Once again, thank you for your support and engagement. It is because of readers like you that we can continue doing what we do.