These are essential tools in various industries, providing compressed air to power machines, tools, and other equipment. However, these machines are subject to wear and tear, and cut-in pressure can affect their performance and longevity.

Contents

Maintaining optimal pressure levels

A pressure differential is one of the critical factors that can affect a process. Cut-in pressure can lead to inefficient operation, while higher maximum pressure can cause damage to the compressor.

Lower levels can be achieved by adjusting the cut-in, which is the pressure drops at which the compressor should start running.

Therefore, maintaining optimal levels is essential for proper functioning.

The air compressor pressure switch may also be affected by the environment in which the compressor operates. Dust or debris buildup on the new pressure switch can cause it to malfunction, leading to incorrect pressure switch readings and potentially damaging the compressor if not addressed promptly.

The air compressor pressure switch role

The air compressor pressure switch acts as a safety mechanism for the compressors, preventing them from reaching unsafe levels. The pressure switch plays a critical role in maintaining the compressor’s performance and preventing damage.

Properly setting the cut-in pressure and compressor pressure switch is essential for maintaining the compressor’s optimal performance and extending its lifespan.

Overall, understanding the functions of the pressure switch and cut-in pressure is crucial to ensure safe and efficient operation.

To ensure the compressor operates safely and efficiently, it’s essential to test the pressure switch regularly and adjust it as necessary.

Several factors affect the pressure on a compressor

- One of the most significant factors is the environment in which the compressor operates. For example, if the compressor is operating in a dusty or dirty environment, the air filter may clog, reducing the amount of air that the compressor can intake, which can cause a cut in pressure.

- The compressor pressure switches have a big role in controlling the cut-out pressure and ensuring that it operates efficiently.

- Another factor that can adjust the pressure on a compressor is the type and quality of the compressor’s parts. Poor quality parts or worn-out parts can result in air leaks, and cut-in pressure this can reduce the amount of air that the equipment can deliver, leading to drops.

Correctly-sized air compressor

It is also a factor that affects the pressure it can generate. Larger compressors can produce higher pressures, while smaller compressors may not be able to adjust the pressure for the air pressure setting.

It’s essential to choose the right-sized compressor for your application to ensure that you get the required levels. Also, different compressor pressure switches have different features, such as an opportunity to adjust the pressure differentials or fixed range settings, and to choose different compressor models and applications.

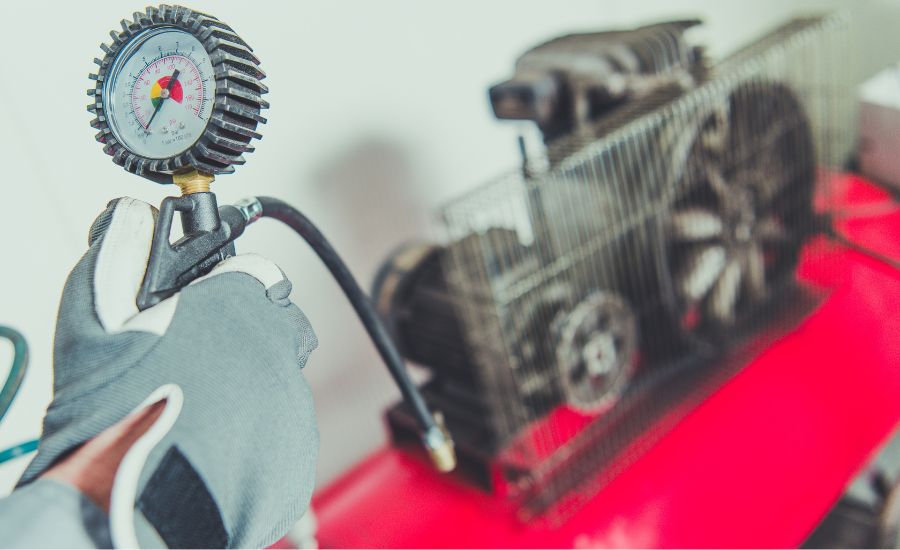

Importance of pressure gauge in air compressor maintenance and working pressure switch

Pressure drops are an essential tool for monitoring pressure. Regularly checking the cut-out pressure can help you identify any pressure-related issues before they cause significant problems.

If the pressure differential indicates that the pressure is up or too down, you should take immediate action to address the issue. To protect it from working at unnecessarily high-pressure levels, it’s essential to choose the cut-in pressure to lower pressure with a pressure switch.

The techniques for control switches

Users are turning the screw on the pressure switch either clockwise or counterclockwise, depending on cut out the press.

This process seems straightforward, it’s essential to consult the manufacturer’s instructions or seek guidance from a professional to ensure that the adjustments are made correctly.

Improperly adjusted configuration can significantly impact the compressor’s performance and efficiency, leading to potential damage and costly repairs.

On-time maintenance

Proper maintenance of the air compressor pressure switch is a factor in achieving peak performance and durability.

Fixed differential pressure switches are an effective way to control air pressure cut in and cut out, ensuring consistent levels and safe operation.

Best practices for maintaining your air compressor’s pressure and efficiency

One top mistake that people make is to overwork air compressors.

Overworking can cause a cut in pressure, resulting in lower efficiency and potential damage to the compressor.

It’s essential to follow the manufacturer’s recommendations for usage, maintenance, and repair to ensure that the compressor operates correctly.

Ideal pressure thresholds for maximizing compressor performance

The pressure on an air compressor is a critical factor that can affect its performance and longevity.

Maintaining optimal levels, monitoring pressure using the fixed differential pressure, choosing the right-sized compressor, and following the manufacturer’s recommendations are essential for ensuring proper compressor operation.

By taking these steps, you can avoid damage to your equipment and ensure that your compressor operates at its best.

Maintaining: tips for optimal performance and pressure control

Additionally, it’s good to regularly check the air compressor to protect it from pressure drops. This may include checking and replacing the compressor motor, drain valve, and other components as needed.

It’s also worth noting that different air tools may require pressure settings, so it’s important to adjust the cut-out pressure accordingly.

For example, some tools may require a lower pressure setting others require higher pressure.

Overall, seeing the functions and maintenance can help prolong the lifespan of your compressor and ensure that it operates safely and efficiently for all your pneumatic needs.

FAQ

How do you adjust cut-out pressure?

To answer the question ” how to adjust cut-out pressure on air compressor”, I can say that the air compressor pressure switch is helpful, cause after you see for sure how to work with the problem.

The air compressor pressure switches consist of the cut-in pressure and the cut-out pressure.

It’s possible to increase the pressure while ensuring safe operation.

The cut-in is a min when there is no more pressure, while the cut-out pressure is the pressure at which the switch turns off the air compressor.

The new pressure switch cut-out pressure setting change, resulting in a higher pressure range. Similarly, the decrease is resulting in a low.

For example, to increase the pressure in the tank, it’s crucial to ensure that the drain valve is closed and the cut-in pressure is set correctly. Cut-in pressure and cut-out pressure are modified using the adjustment screw counter clockwise on the pressure switch.

It is placed within the right scope. Exceeding the maximum pressure differential can result in damage to the compressor or even cause it to fail.

Therefore, monitoring the fixed differential pressure is important.

In summary, with the cut-in pressure, the cut-out pressure, and the adjustable pressure differential, Users see the whole process going on.

Regular monitoring of the fixed differential pressure helps you identify and address pressure-related issues before they become significant.

At what PSI should the air compressor cut in and out?

Air compressors are versatile and reliable tools used in a variety of applications. However, to ensure their proper functioning, it’s important to consider the cut-in and cut-out pressures.

Although the cut-in and cut-out pressures are not similar for different tools, it is essential to check the manufacturer’s specifications to determine the appropriate settings for your specific compressor.

By correcting cut-in and cut-out pressures, you can prevent frequent cycling, it can reduce the compressor’s lifespan and efficiency.

Good idea to have the cut-in pressure to 20-30 PSI below the cut-out pressure. When the cut-out pressure is set to 150 PSI, the cut-in pressure is set between 100-115 PSI. This helps to ensure it has enough time to build up pressure before starting, which can optimize its performance and increase its efficiency.

A proper setting of the cut-in and cut-out pressures is crucial for maintaining optimal operation.

A good idea to monitor and adjust the same pressure settings regularly to ensure that the compressor is functioning efficiently and to extend its lifespan. By doing so, you can avoid costly repairs and downtime, and ensure this process is totally fine.

How do I adjust the pressure on my air compressor?

Choosing the pressure is crucial for achieving performance, but it can also be a daunting task for those who are unfamiliar with it.

To do things more complicated, the pressure switch – a critical part in regulating the pressure – may be adjustable, depending on the compressor’s model.

For those with a fixed range pressure switch, the cut-in and cut-out pressure are predetermined and cannot be altered. The pressure switch uses flexibility to manually change the cut-in and cut-out pressures to meet their specific needs.

The lower maximum pressure and cut-in settings can have several benefits for an operation. By reducing the maximum pressure, the compressor operates at a lower stress level, which can help to extend its lifespan and reduce maintenance costs.

Lower cut-in settings mean that the compressor turns on at a lower pressure level, resulting in more frequent but shorter run cycles. This can improve energy efficiency by reducing the amount of time the compressor spends idling and can help to prevent overheating and other issues.

However, it’s important to note that lowering the pressure settings too much can result in reduced performance and may not provide enough pressure for certain tools or applications. It’s essential to find the right balance between energy efficiency and performance to ensure optimal compressor operation.

Therefore, taking the time to make the pressure difference on the compressor can pay off in the long run.

Summary

In summary, the cut-out pressure on the compressor is a critical process that can significantly impact the performance and efficiency of the compressor.

The comprehensive guide presented in this text provides detailed steps and instructions – on how to adjust the cut in pressure, including identifying the cut in pressure switch, disconnecting the power supply, changing the pressure switch, and testing the compressor.

It is crucial to take proper safety measures when working with an air compressor and to seek professional assistance if unsure about the process. Learning how to adjust cut-out pressure on air compressor is essential for maintaining safe and efficient operation.

Read More: How to Set Air Compressor Pressure